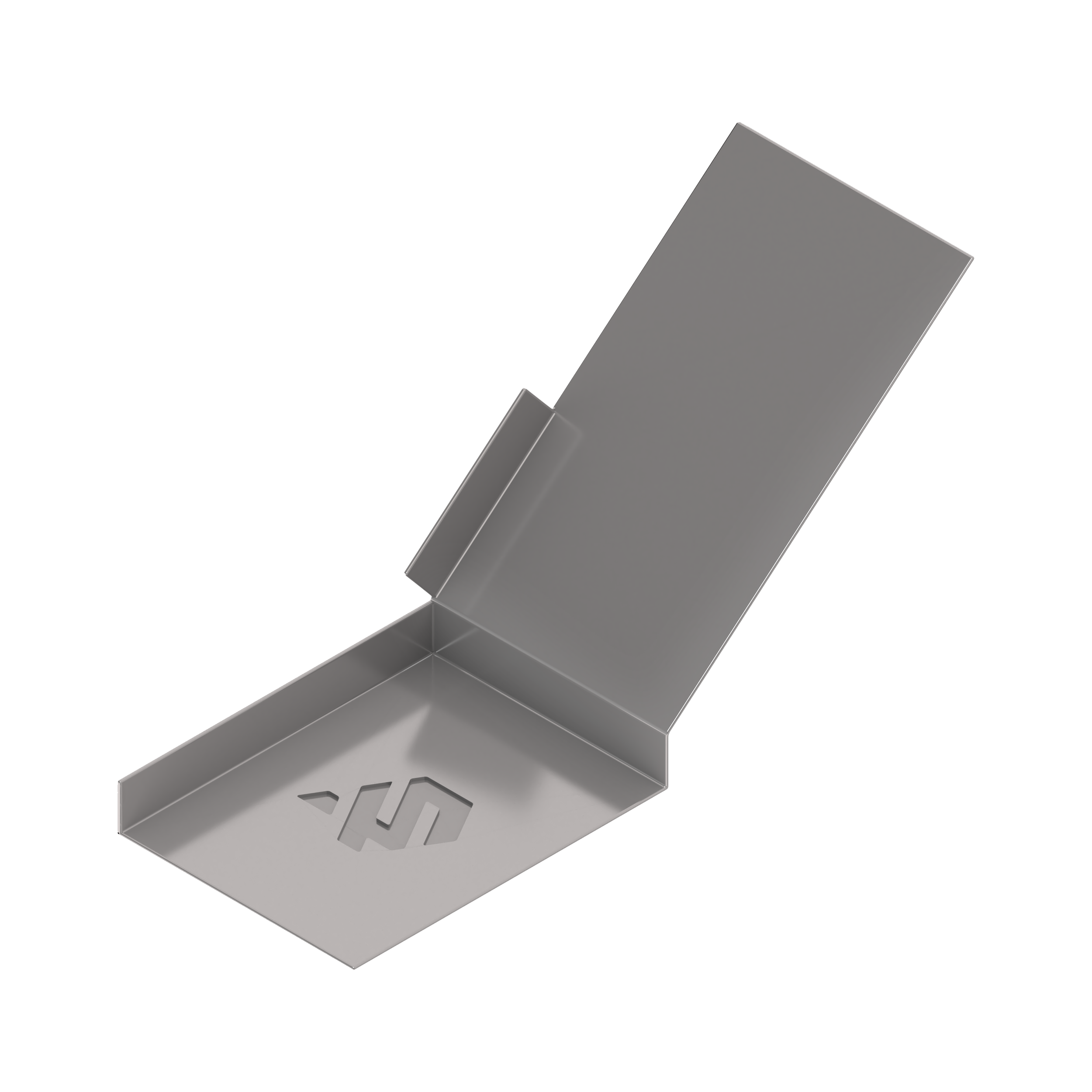

Cavity Tray (TSCT)

The purpose of a cavity tray in a cavity wall is to prevent moisture from penetrating the inner leaf of the wall by redirecting water that enters the outer leaf back to the outside. It is a waterproof barrier installed at specific points, such as above window and door openings or where roofs intersect walls, to intercept and channel water out through weep holes, maintaining the wall’s integrity and preventing dampness inside the building.

The requirement for non-combustible damp trays to be used on buildings that exceed 18m in height lead to the development of our CT-304 cavity tray.

TSCT

Constructed out of grade 304 stainless steel, our A1 rated cavity tray product meets the requirements of Part B of the building regulations, specifically in relation to the ban on combustible materials in and on the external walls of buildings: Consequential amendments following the laying of the Building (Amendment) (England) Regulations 2022.

Whilst providing a strict water barrier, the properties of grade 304 stainless steel means it has high resistance to corrosion which, in addition to its lightweight and flexible properties, make it the perfect material to form the CT-304 cavity tray.

Resources

Our Cavity Tray products are live on the NBS Product Selector allowing for ease of specification.

Our Accreditations

We hold a UK Certificate of conformity Factory Production Control to Harmonised Standard BS EN 1090-1:2009 +A1:2011 (Load bearing structural steel components up to EXC 2 according to BS EN 1090-2)

This certification covers our masonry support systems up to execution class 2 and therefore, we now offer a UKCA mark for these products in accordance with declaration method 3a.

We also hold a Gold level certification from Constructionline, this shows our commitement to ensuring all our onsite H&S procedures are up to the correct standard.